The presence of archaeological findings showing that woven fabrics were used in 6500 BC reveals that weaving, a method of creating a textile surface with two yarn systems, was known at least 8000 years ago. These old woven fabrics belonging to the Neolithic Stone Age and found in carbonized form were also discovered as a result of the excavations performed in our country

It is also suggested that the first fabrics, which were not different from the weaving forms we know today, had been inspired by the lattice weave technique. The warp system was used to be hung vertically, and the wefts were passed through manually, so that the two yarn systems could be passed through each other to finally form a weave perpendicular to each other. In this case, the weaving plane was previously being used vertically. The development of this primitive weaving technique and its transformation into a weaving machine coincides with 4000 BC.

In the early periods of weaving, although the beginning is not known exactly, weaving looms with the first horizontal weaving plane operated by human power were used in the Eastern sphere. Shed opening mechanisms, which were not known in Europe until the 3rd century AD, were significantly developed in China. Even complex patterned fabrics could be woven with systems that we can call primitive jacquard mechanisms.

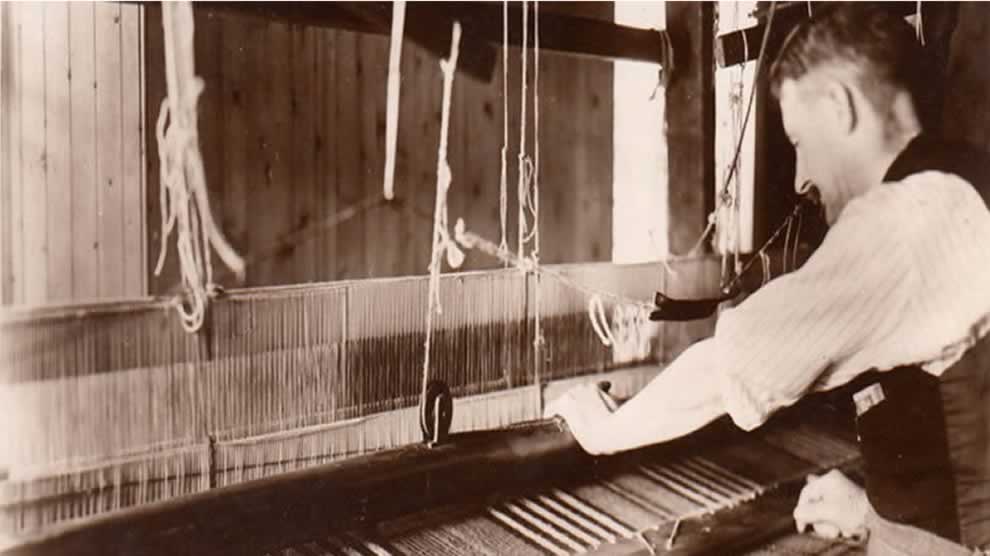

In the 12th century, the standard handlooms were the most common weaving systems. The warp beam was attached to the back and the cloth roller to the front and the warps were stretched in the horizontal plane. The reed was articulated to the chassis to oscillate from above. The heald frames were operated by foot, pressing with the help of pedals with frames that were located under the warp layer. There were no piques and the shuttle was a manual process.

In Continental Europe, a multi-head weaving loom emerged in 1600, where a single person could weave 24 pieces side by side and at the same time.

The weaving loom's turning into a weaving machine was made possible by the mechanization of 3 basic systems: picking, opening shed and beating systems, and the use of another power instead of arm power. In 1500, Leonardo Da Vinci thought of a water-powered loom. Although Gennes in 1678 and Vaucanson in 1745 tried to make such machines in France, they could not achieve it.

An English inventor named Dr. EDMUND CARTVRIGHT invented the first commercial mechanical weaving loom in 1785. Around this time, the invention of the warp sizing machine in 1804 by two Englishmen, Johnson and Radcliffe, boosted the rapid spread of mechanical weaving.

While the studies on the development of picking systems and the mechanization of the loom were continued in England, the patterning factors had gained significance in France. Apart from simple weaving, they worked on shed opening systems for complex patterns. In 1725, Basile Bouchom invented the first automatic shed opening device, working with a punched cardboard to select the warps that needed to be lifted. Later, Falcon used the punched card in 1728. Vaucanson developed these mechanisms in 1746, and the development of shed opening systems culminated in 1801, when J. M. Jacquard invented the eponymous jacquard machine.

Shed opening systems have also been integrated into mechanical looms. In 1835, J. P. Reid and T. Johnson made the first shuttle changing device, ensuring multi-colored picking. Hacking introduced the well-known cam-driven changeover mechanism in 1868.

The most important invention on the mechanical loom was made in 1867 by Hattersley and Simit as they completed the "kighley" dobby. Considered as “jacquard of the poor,” this shed opening device had a solid construction. It did not have as comprehensive a patterning system as the jacquard system, but it ran faster.

After the loom was evolved to be more mechanical, a new problem arose. This problem was the need to stop the weaving loom in case of any yarn breakage or malfunction and interrupt the work to change the shuttle in case of running out of weft cop. In 1796, a mechanism that stops the loom as short weft is picked was invented by Robert Miller. This system is being used even in today's conditions.

Later, the mechanisms that stop the loom in case of weft breakage or the shuttle ran empty were invented. In 1822, British Engineer R. Roberts came up with the perfect weaving machine, combining all the developments up to that point and incorporating all available mechanisms.

In 1890, it was thought to wind the weft cops directly on the loom, but this idea was only realized during the 1950s, when Leesona company developed the Unifil system in the USA. The problem of replacing the empty weft cops was solved by J. H. Northrop, who immigrated to the US, with the completion of the automatic bobbin changing system, which was started in England, in 1894. In 1910, Ruti firm in Switzerland tried the weft cop magazine, which had a large capacity.

The extraordinary developments in recent years also uphold this view. For instance, although it was thought for the first time in 1914 that the weft could have been picked with an air jet, it was the 1980s when it had to be realized and gain commercial importance.

The most important factor that encourages the continuation and development of weaving machinery production is that a textile surface that can replace woven fabrics has not been found yet.

Considering that the weft can be carried with hooks, the first patent was granted in 1898. On this subject, the Gabler system was developed in 1925, and the Dewas system was created in 1930. Another alternative has been the gripper projectile loom system, in which the gripper arm passes only the required weft length through the shedding. Pastor got the first patent for this picking system in 1911. This picking system was developed, and the first shuttleless loom having commercial importance, the Sulzer projectile loom, appeared in 1953.

The manufacturing industry of weaving machines began closely monitoring these developments and controlling the market more carefully with the declined popularity of woven fabrics in the 1950s and 1960s and the reduced importance of knit products in the textile markets. With the development of technology, however, woven fabrics became popular again during the 1970s, and various fabrics were produced and put on the market in line with consumer demand.

Authorities easily say that an alternative that can compete with weaving is not yet on the horizon and that weaving technology in the production of textile fabrics will continue to be unrivalled for foreseeable future.

Konunun uzmanları dokumayla boy ölçüşebilecek bir alternatifin henüz ufukta görülmediğini ve tekstil kumaşları üretiminde dokuma teknolojisinin şimdilik rakipsiz olduğunu rahatça söylemektedirler.

Revolutionary developments in electronics and computers in the last 20 years have been reflected in textile weaving. As a result, fabric production and quality have increased. Fabric production has been cheapened by reducing costs. As a result, woven fabrics will remain popular for a more extended period of time.