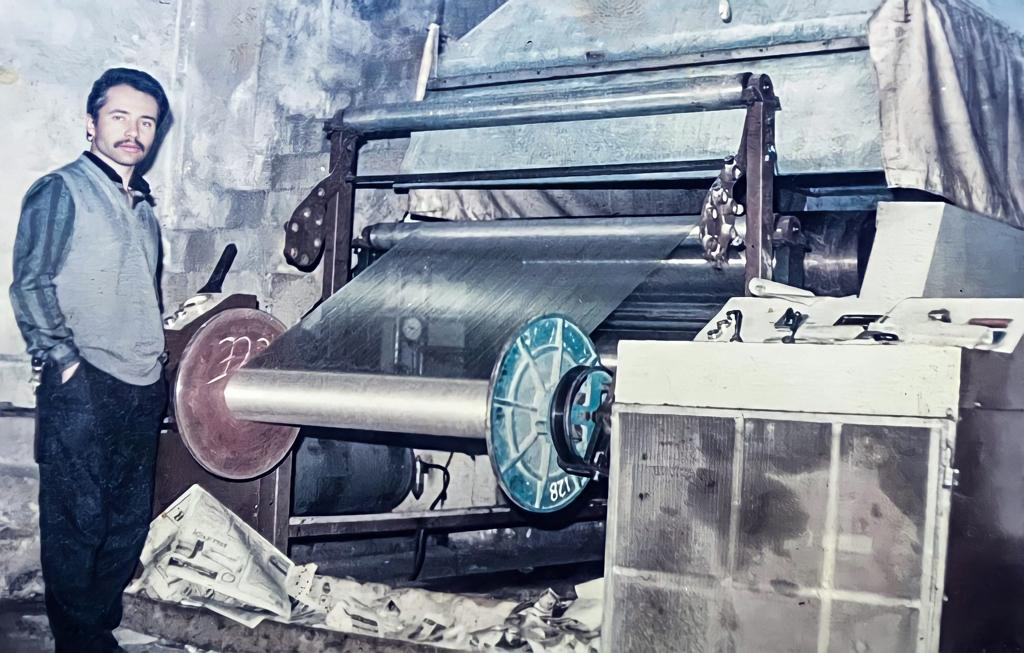

In 1990, the project for the production of a fixed padded warping machine and two sectional sizing machines was carried out by Ramazan Alper.

In 1995, 18 Wamatex weaving machines, 2 sectional sizing machines of our own project, fixed padded warping machines, and a team of 30 people were operating on an area of 1300 m2 in Bursa Küçük Balıklı Neighborhood.

2021 yılı itibariyle Bursa Demirtaş Organize Sanayi Bölgesindeki haşıl tesisimiz, 4 adet seri çözgü, 8 adet haşıl makinası, 10 bin metre karede 85 personel ile hizmet vermektedir.

To prepare direct warp, the yarns coming from the creel are wound on the beams in parallel. The number of warp yarns wound on the beam is as much as the creel capacity. The prepared beams are combined with the transfer process to reach the required number of warps in weaving. If sizing is required, the beams are loaded directly into the sizing machine and combined during the sizing process.

Sizing is a viscous liquid with adhesive characteristics in various and suitable chemical compositions prepared to increase the durability of the warp yarns to be used in weaving and to prevent static electricity. This is the formation of an invisible layer, lubricating and strengthening the warp yarns by passing them through the sizing agent to protect the warp yarns from the abrasive forces that may occur during weaving. The sizing process helps to preserve the chemical properties of the yarns. It adheres the fibers on the surface of the warp yarns to the yarn body. It also ensures that the fiber ends on the yarns stay on the yarns.